InP100 Product Platform

Integrated design and manufacturing services for a broad range of photonic devices including FP & DFB Lasers, SOAs, RSOAs and Detectors. This common design and manufacturing framework for InP photonics devices, uses established and reliable process modules to produce a broad range of device types on 100mm wafers. We have introduced the InP100 platform approach at exactly the point when optical communications and sensing applications require a single-chip, nanoscale solution to meet volume, power, performance and cost demands.

InP100 Product Platform Key Features

- 100 mm wafer size – up to 125,000 die sites per wafer

- High yield, proven reliability

- Scalable to high volume

- Optimised architecture for SiPh flip-chip bonding

- On-wafer facet etch and optical coating

- Non-hermetic compatibility

- Optimised architecture for SiPh flip-chip bonding

- Reduced time to market

InP100 Platform Process Module Technology

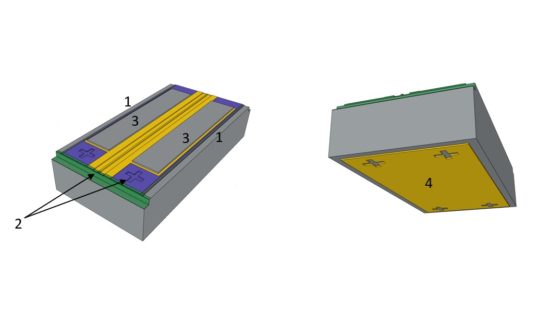

InP RSOA chip optimised for SiPh Flip-Chip Assembly

Key design features:

- Vertical alignment surfaces +/- 5 nm height accuracy to optical mode centre (z-axis)

- Etched facet with self-aligned front-side fiducials to both ridge (x-axis) and facet (y-axis)

- Metal pads optimised for flip chip bonding. Optional AuSn solder

- Backside alignment fiducials, and chip IDs

- Particle-free front-side

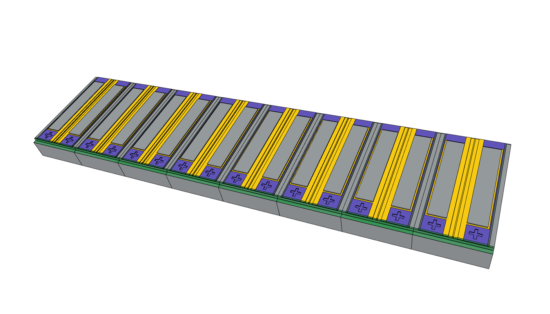

InP RSOA 8x-array for SiPh Flip-Chip Assembly

Key design features:

- Vertical alignment surfaces +/- 5nm height accuracy to optical mode centre. (z-axis)

- Etched facet with self-aligned front-side fiducials to both ridge (x-axis) and facet (y-axis).

- Metal pads for flip chip bonding. AuSn solder optional

- Backside alignment fiducials, and chip IDs

- Single chips or multi-element arrays

![]()

![]()

![]()

![]()

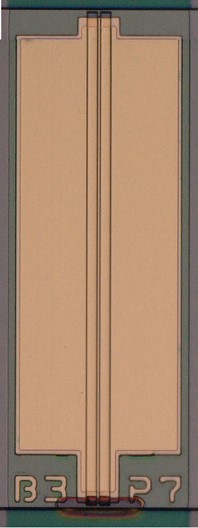

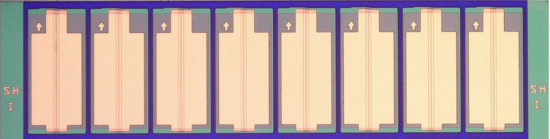

Straight and angled etched facets Vertical and angled etched profiles / Accurate vertical alignment

![]()

![]()

![]()

… Self-aligned front-side fiducials .. Back-side alignment fiducials and chip IDs….CV….…. .Optimised low resistance metal stack… .. ..…

![]()

![]()

![]()

Co-planar contacts AuSn solder on III-V On wafer optical coatings

Example Devices

Wide operating temperature 1310nm DFB

- Application: 5G LTE

- Designed for CW operation at 25mW ex-facet output power

- Functional from -50C to +95C assembled in TOSA packages

- Performance achieved through optimised MQW active region, grating design, and cavity length

High Power 1310/1550nm DFB for LIDAR

- 100mW at 1310nm at 25°C / 60 mW at 1550nm at 25°C

- Higher powers achievable through further optimised epi/grating designs for longer cavity lasers

- LWs <300kHz

- SMSR > 50dB

- Complementary O-band and C-band booster SOAs

DFB laser diode arrays designed for use in CW-WDM MSA compliant applications

- 45mW per channel CW operation

- 400GHz channel spacing around 1300nm

- Operating temp 20°C – 70°C

- AlInGaAs MQW active region

![]()

Contact Sivers Photonics

For more information about Sivers Photonics, or to discuss your photonics project requirements.