Foundry Services

Scroll Down

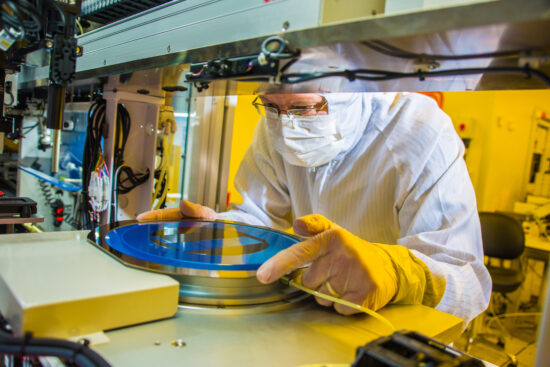

Our foundry provides end-to-end design, manufacture and qualification for early phase prototypes and high-volume production, supporting up to 100mm wafer sizes on InP, GaAs, GaSb and GaN substrates. We have an extensive portfolio of unique production process IP, essential to high-quality, reliable, volume manufacturing.

FRONT-END-OF-LINE (FEOL)

Design

- 2″, 3″ and 4″ wafers

- All major III-V material systems

- InP, GaAs, GaSb and GaN processing available

- Library of InP epitaxy designs from 1270 – 1650 nm

- Integrated design and manufacturing services for a broad range of photonic devices – FP & DFB lasers, SOAs, RSOAs, Detectors

x

x

x

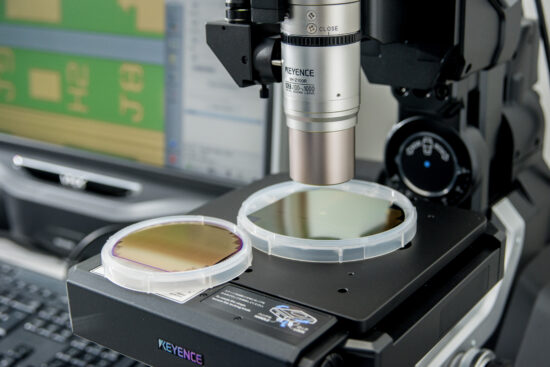

Lithography

- E-beam, stepper and contact lithography

- Front to back alignment

x

x

x

x

x

x

x

MOCVD

- InP DFB overgrowth

- BH process TBC

- Zinc diffusion TBC

x

x

x

x

x

Wafer Processing

- On wafer etch facet and optical coating technology

- Wet/dry semiconductor and dielectric etching (ICP-RIE/RIE)

- PECVD Passivation (Si3N4/SiO2)

- Evaporated/sputtered metal

- AuSn evaporated solder pads

- Film stress design and balance

- Extensive metrology (including SEM, AFM)x

x

We provide custom mechanical feature optimised for hybrid integration to silicon photonic.

BACK-END-OF-LINE (BEOL)

Facet Coating

- AR and HR dielectric optical facet coating at bar level

- High volume capacity with automated bar loading

- Facet coating qualified for non-hermetic packaging

- Wavelength range: 350nm to >3µm

- Reflectivity range: -40dB to 90%

x

x

x

x

x

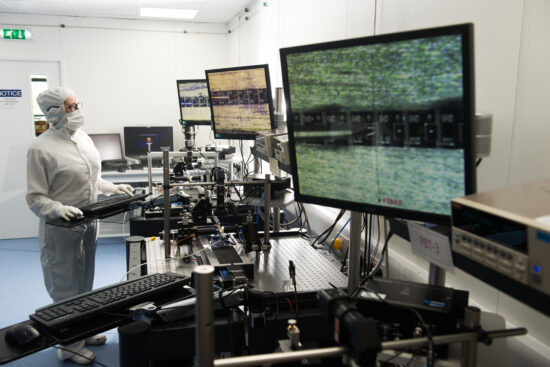

Testing

- Automated high-volume bar testing

- LIV and spectral testing of edge emitters up to 55°C

- > 2million lasers/month testing capacity

- Chip-on-submounts

- Detailed spectral analysis up to 85°C

- Farfield 2D beam analysis

x

x

x

x

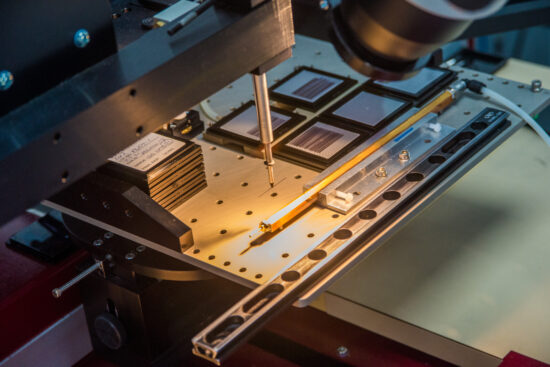

Singulation and Assembly

- Automated bar cleave and device singulation

- Typical delivery formats:

- Known-good-dies on tape (6” ring frames)

- Singulated bars on tape (6” ring frames)

- Singulated chips on submounts

- Bars in Gel-Pak

x

x

x

x

Reliability & Qualification

- HTOL and ALT testing to Telcordia GR468

- 2k hrs, 5k hrs & 10k hrs test durations

- Continually monitored ACC and APC, individually addressable Newport ILX system

- Up to 500mA, 40°C – 120°C

- Damp-heat testing (typical 85°C/85%)

- Detailed analysis, reliability and qualification reports

x

x

x

Contact Us

We’d love to show you how Sivers Semiconductors can help transform your business—contact us for further information.